Products

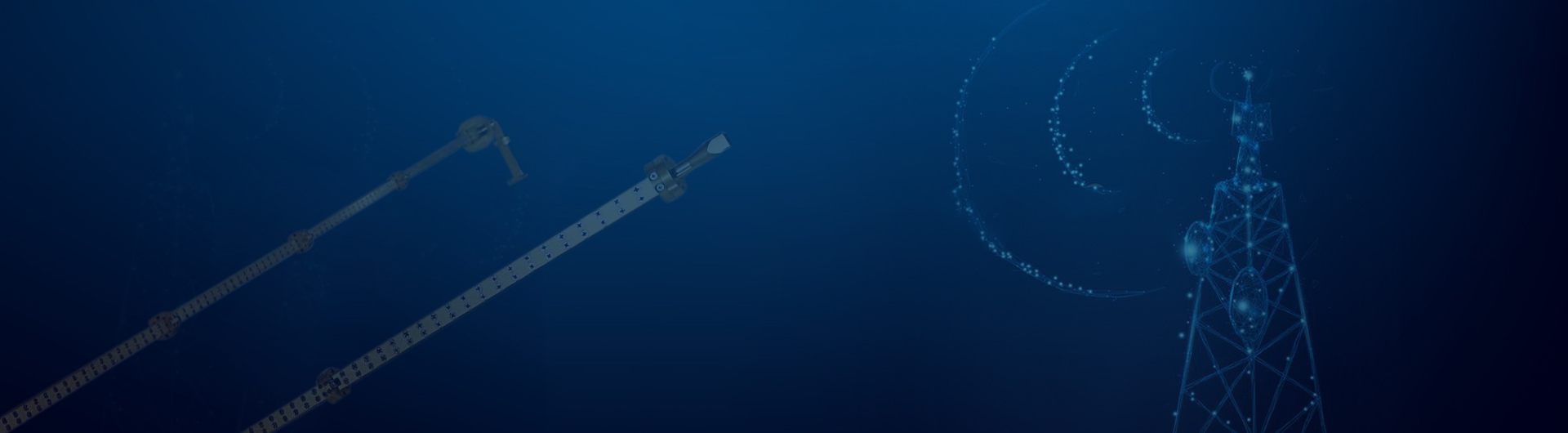

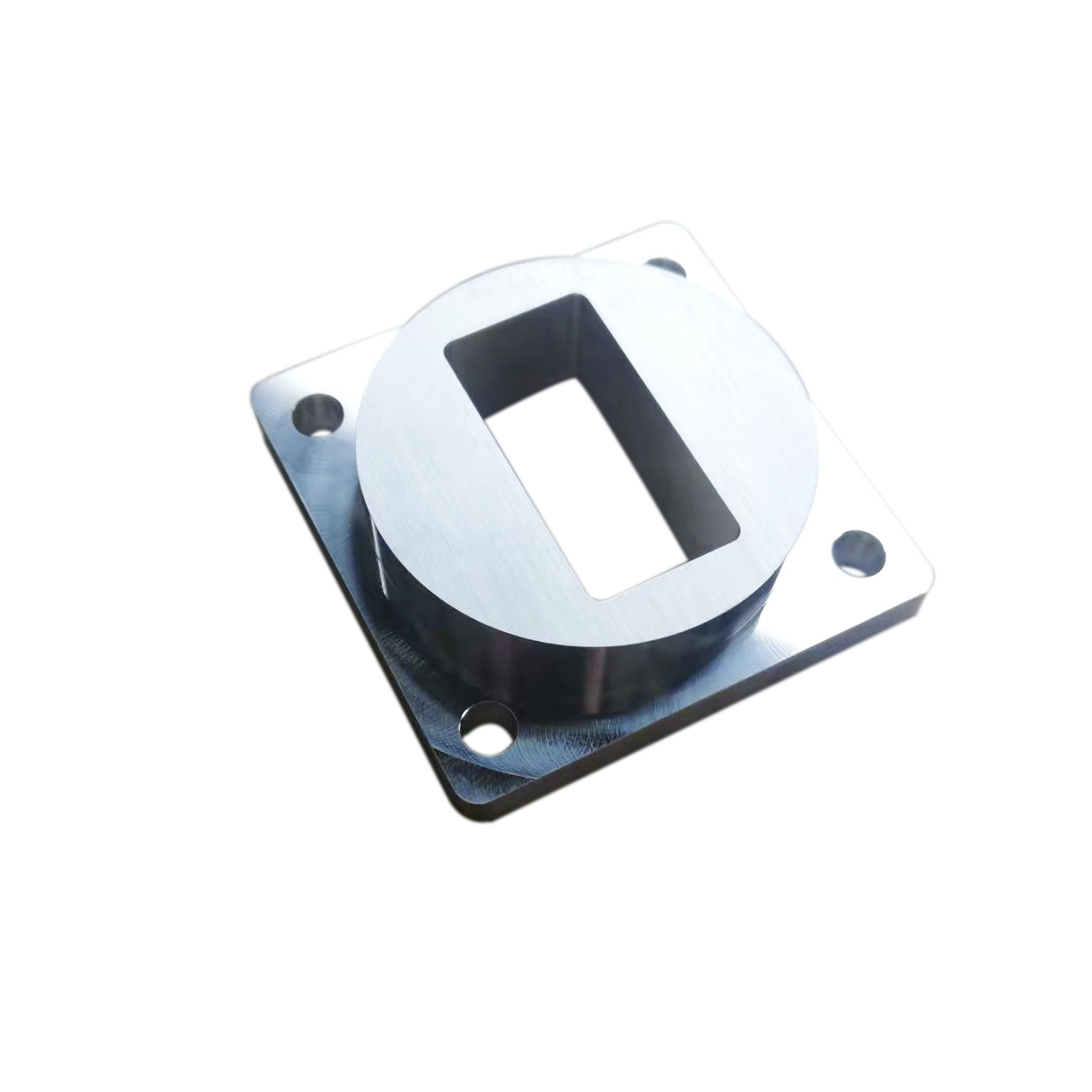

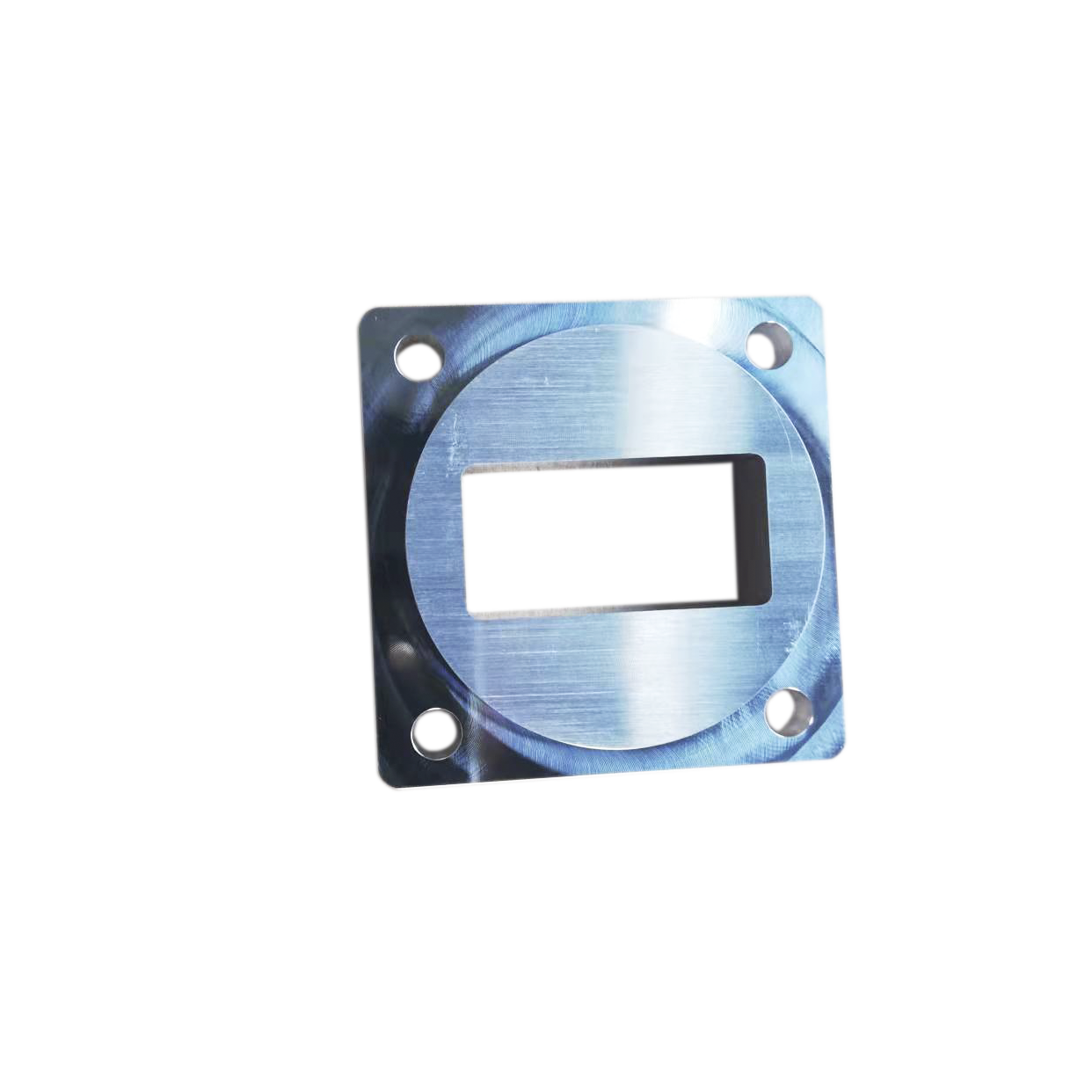

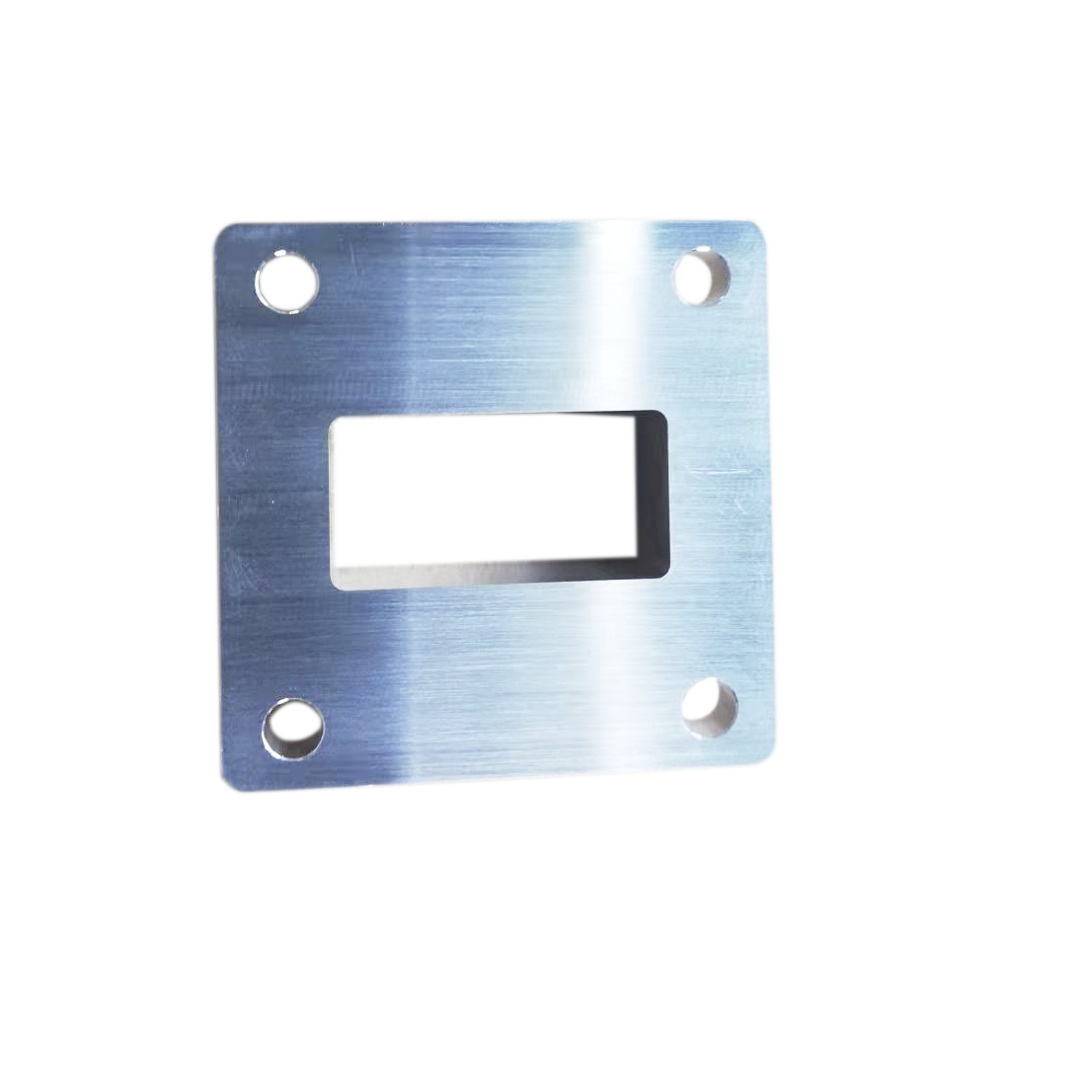

OEM Customized Mmw Website - WR90 standard welded waveguide flange – XIXIA

OEM Customized Mmw Website - WR90 standard welded waveguide flange – XIXIA Detail:

Connector of waveguide flange:

After obtaining appropriate waveguide components, the assembly and maintenance of waveguide components and interconnection devices will also affect the performance. The connector of waveguide flange is a problem prone area. If gaskets are not used, the surface of the flange needs to be kept clean and flat. Any damage, dust, or peeling of the metal plate may cause RF leakage, and misalignment may degrade performance. The bending and distortion of the waveguide may also form stress cracks due to thermal cycling and mechanical stress. The higher the frequency of the waveguide, the more sensitive the system performance is to correct assembly and maintenance.

For example, for a waveguide with a flange connection, each corner of the waveguide has a specified torque. If one corner of the waveguide has more and less torque than the other, a small gap will reduce the VSWR and insertion loss performance. RF leakage may also occur. This may occur when the gasket gradually deteriorates with age or after heating and cooling cycles. Some threaded screws still support even under vibration and heavy load. The method of ensuring stable fastening can be adopted as long as it does not affect the RF performance and flange clamping.

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for OEM Customized Mmw Website - WR90 standard welded waveguide flange – XIXIA , The product will supply to all over the world, such as: Bulgaria, Nigeria, Oman, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly